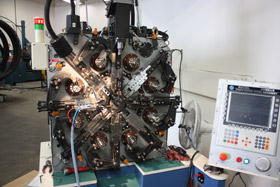

Custom Precision Wire Forming

At AARD Spring & Stamping, we specialize in precision wire forming, utilizing CNC bending and 8 axis CNC forming equipment, as well as a variety of value added services. Our capabilities include manufacturing of straight formed ends with wire diameters ranging from .012″ (.3048mm) to .531″ (13.48mm) in a variety of metals. We produce large & small torsion and double torsion bars, offering a wide range of finishes, such as anodizing, black oxide, and shot peening just to name a few.

For more information on all of our precision wire forming services, see the table below or contact Aard directly.

Portfolio

Precision Wire Forming Capabilities:

| Fabrication Process | CNC Bending CNC Forming- 8 axis Cutting | Flattening Straightening |

| End Type | Straight | Formed Ends |

| Finishes | Anodizing Black Oxide Oiled Passivation Phosphate Powder Coated | Shot Peen Tumble Deburr Zinc

|

| Wire Form Products | Torsion Springs with Forms Double Torsion Torsion Bars

| |

| Wire Diameter | Min .012 in .3048 mm | Max .531 in 3.48 mm |

| Finished Wire Product Tolerance (+/-) | as close as ±3° on forms | |

| Materials | Alloy Steel Beryllium Copper Brass Bronze Carbon Steel Chrome Silicone Copper | Hastelloy Inconel Monel Music Wire Stainless Steel 300 series and17-7 |

| Industry Standards | ANSI American National Standards Institute ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials | ISO International Organization for Standardization ISO 9001:2015 Mil-Spec Military Specifications RoHS Restriction Of Hazardous Substances (Compliant) SMI Spring Mfg Institute |

| Preferred File Formats | PDF Portable Document Format |