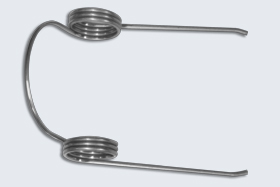

Custom Double Torsion Spring for the Medical Industry

A customer in the medical industry came to AARD Spring & Stamping in need of a custom double torsion spring. The client provided our team with a CAD drawing, and our experts designed the spring according to their exact needs and specifications. We used .035 galvanized music wire for the part, in conjunction with our state of the art equipment. The use of this particular wire ensured reduced tangling and deformation.

We worked within tolerances of ± 3° on angles. We packaged the torsion spring on tacky board, and performed a series of inspections. Providing JIT delivery of the product to the client in California, we now produce 36,000 units for them annually. The client is highly satisfied with all aspects of production, including our customer service. To learn more about this project, or for more information on our other products and services, please contact AARD Spring & Stamping.

Double Torsion Spring Project Highlights:

| Product Design | Double Torsion Spring |

| Tightest Tolerance | ± 3° on angles |

| Material | .035 Galvanized Music Wire |

| Industry | Medical |

| Volume | 36,000 Annually |

| Delivery Time | JIT |

| Location | California |

| Packaging | Tacky Board |